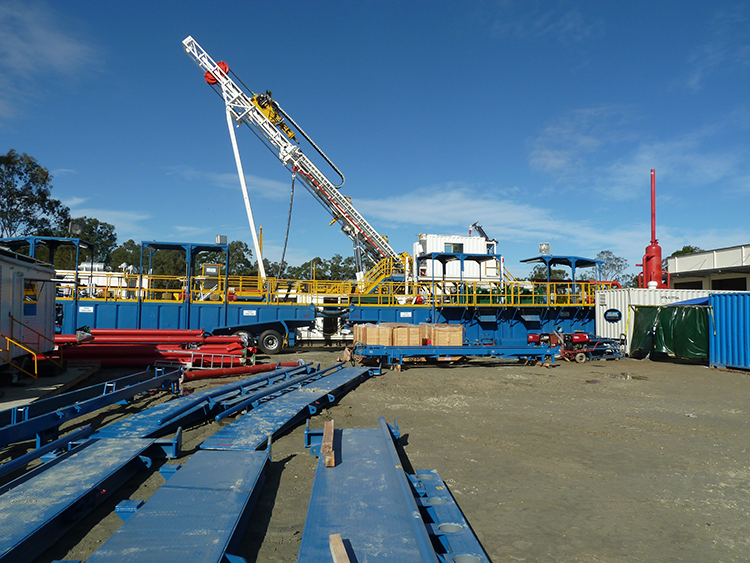

斜井鉆機

發布時間:2019-07-23

|

斜井鉆機Inclined well drilling rig |

RG MYC45-X |

RG MYC75-X |

|||

|

鉆進能力 Drilling capacity |

最大鉆孔深度 Max drilling depth |

m |

1000 |

1500 |

|

|

最大鉆孔直徑 Max drilling diameter |

mm |

φ650 |

|||

|

鉆桿直徑 Diameter of drilling pipe |

mm |

89 / 102 / 114 |

|||

|

鉆桿長度Length of drilling pipe |

mm |

6000(Optional 9500) |

|||

|

拖掛底盤 Trailer-mounted chassis |

發動機品牌 Engine brand |

/ |

Cummins |

||

|

發動機功率 engine power |

kW |

264 |

317 |

||

|

額定載荷 rated load |

kg |

13000*3 |

|||

|

最高車速 Maximum speed |

km/h |

70 |

|||

|

輪胎型號 Tyre size |

/ |

12.00R20-20PR |

|||

|

井架 Mast |

角度調節 angle adjustment |

/ |

45~90°(5°調節一次)(every 5° for adjustment) |

||

|

行程Stroke |

mm |

9000 |

15000 |

||

|

進給系統 Feeding system |

提升力 Lifting force |

kN |

490 |

750 |

|

|

提升下放速度 Speed of lifting |

m/min |

0~17.2 |

0~36 |

||

|

最大加壓力 Max. pressuring force |

kN |

40 |

80 |

||

|

動力頭 Power unit |

扭矩 Torque |

N.m |

0~15000 |

0~20000 |

|

|

轉速 Rotary speed |

r/min |

0~170 |

0~160 |

||

|

內徑 Inner diameter |

mm |

76 |

|||

|

管匯壓力 Manifold pressure |

Mpa |

21 (泥漿slurry+空氣air) |

|||

|

泥漿泵 Mud pump(Optional) |

最大壓力 Max pressure |

Mpa |

4.5 |

/ |

|

|

最大排量 Max displacement |

L/min |

855 |

/ |

||

|

工具卷揚Tool winch |

提升力 Lifting force |

kN |

30 |

||

|

運輸尺寸 Transport dimension |

長×寬×高Length ×Width × Height |

mm |

13800×2550×4000 |

||

|

整機重量Overall weight |

t |

32 |

|||

1.井架上段輔助支撐,在傾斜角度超過20°時安裝,以保證井架穩定性 90°井架垂直狀態 ,井架最大傾角 45°,每次最小調整角度 5°45°時最大提升力400 kN

2.液壓伸縮套裝井架,井架符合API 4F規范,適用API Range 2 鉆桿及API Range 3 套管.

3.頂驅最大行程 15,000 mm (49 ft)安裝輔助支撐不需要吊車,僅用5T叉車

4.底座凈空高 2500 mm,滿足安裝28-21環形BOP及四通要求,轉盤梁最大靜載荷 (75 metric ton),鉆臺一部分可以隨鉆機一起運輸

5.設計制造符合API SpecQ1、4F、7K、8C、16C及APIRP500、等規范,執行GB/T 30216-2013、GB1589-2016標準。采用“以人為本”設計理念,強化安全保護和檢測措施,滿足HSE規范要求。

1. The upper support of the mast is installed when the inclined angle is more than 20°, which can make sure the stability of the mast. When it is in 90° condition, the mast is vertical. The maximum inclined angle of the mast is 45°. Minimum adjustment angle for every time is 5°. When it is in 45° condition, the maximum lifting force is 40metric ton.

2. The mast is matched with hydraulic telescopic casing, and then the mast is conformed to API 4F, which is suitable for API Range 2 DP and API Range 3 casing pipe.

3. Max. stroke of the top drive is 15,000 mm (49 ft). Crane is not used for the installation of the auxiliary support, only 5T forklift is adopted.

4. The headroom of the substructure is 2500mm, meeting the needs of the installation of 28-21 BOP and four-way joint.

5. The design and manufacture conforms to API SpecQ1, 4F, 7K, 8C, 16C and APIRP500, performing the standard of GB/T 30216-2013 and GB1589-2016. The design idea of people orientated is adopted, intensifying the methods of safety protection and inspection to meet the needs of HSE regulation.